Intuitive touch screen operation.

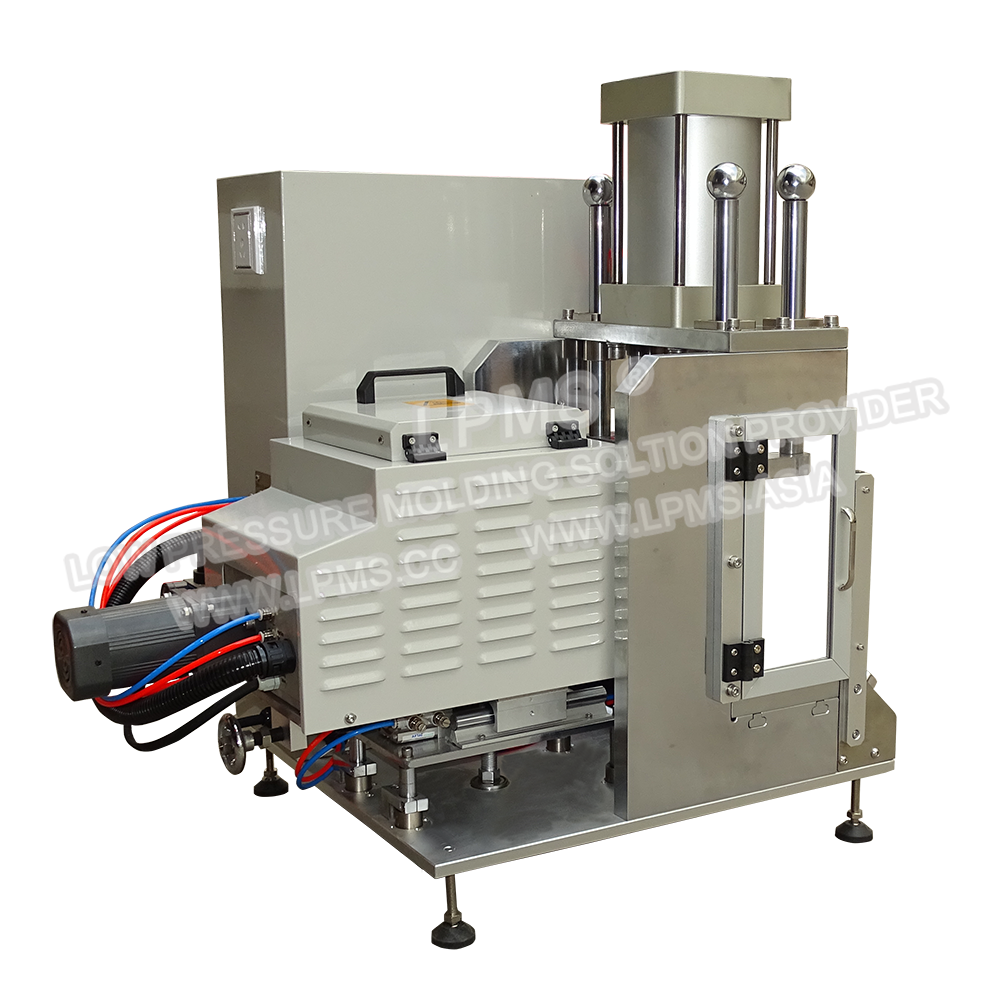

7 liter melting tank integrated into machine.

LPMS specially designed melt-on-demand tank can melt down the resin swiftly and evenly.

The gear pump is made of hard-wearing material,which is stable,injection volume accuracy ±0.1g,maximum shot size is 5g/s.

Injection pressure range 1~50kg, which can be controlled by the pneumatic safety valve. LPMS also have option like electronic safety valve, which means the injection pressure can be set more precisely from the PLC.

Over temperature alarm and automatic heating stop functions.

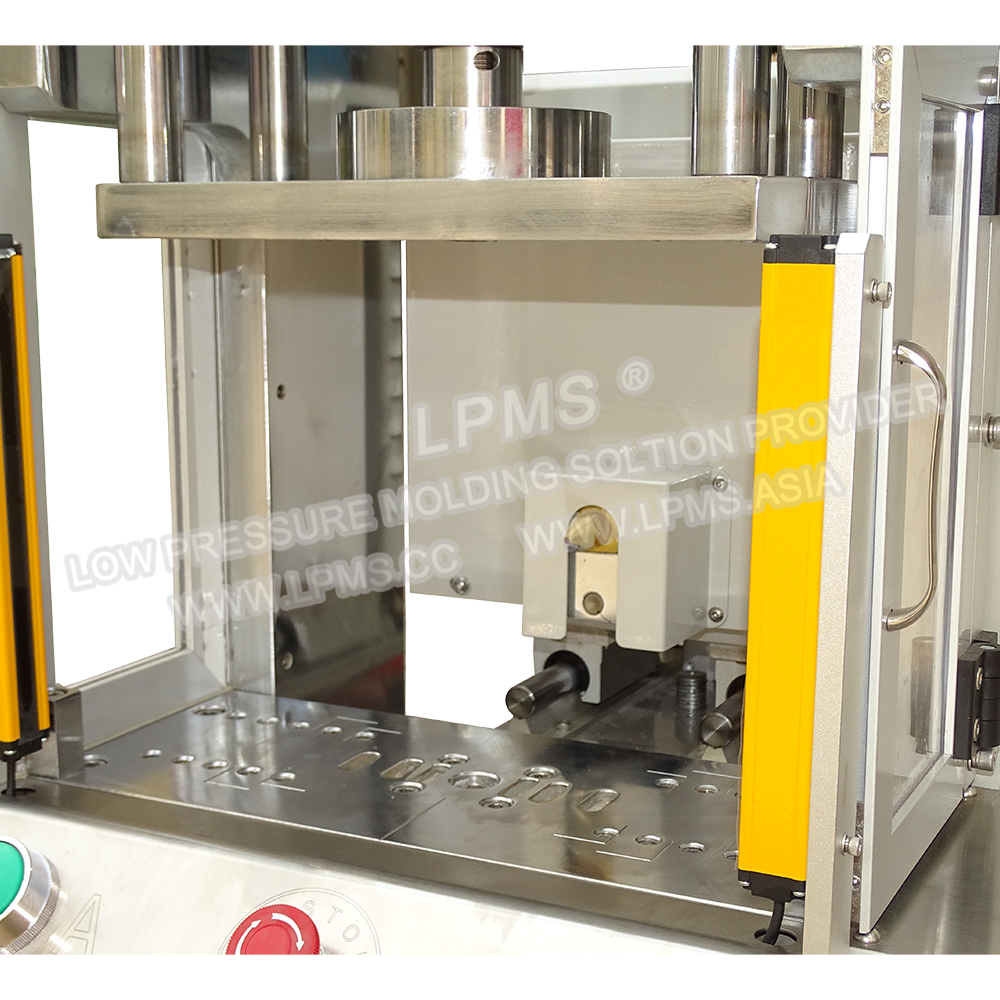

Safety light curtain and two safety buttons protect workers during the operation.

Ejection system.

Application

LPMS? machines are engineered for low pressure molding, using specialty resins to encapsulate delicate parts, like automotive electronics, PCBA, coil, fiber-optic, LED lighting, cable, etc.

The benefits of side injection is that when one large cavity being encapsulated from the center of the mold, which can prevent the gate mark from the center of product.

Specification

Machine Size / Weight | 29.13 in x 37.40 in x 37.79 in / 595 lbs |

Working Station Height | Optional |

Packing Size / Weight | 31.50 in x 41.34 in x 46.06 in / 661 lbs |

Melting Tank | Melt on demand 7 liter x 1 |

Auto Feeding System | Optional |

Maximum shot size | 5.8 g / RPM |

Injection rate | 5 grams / second |

Gun Model & Tip | LPMS-G02 x 1 / 36.4° or 90° |

Heated Hose | N/A |

Electricity | 200-240VAC / 1 Phase / 50 Hz |

Temperature Control Zones | 2 |

Temperature Range | Ambient up to 250°C / 485°F |

Max .Power | 5 Kw |

Pump Motor | 120 W |

Min. Air Pressure | 0.5 MPa | 73 Psi |

Air Consumption | 3.5ft3 / min |

Clamping | Air Cylinder |

Clamping Force | 1.2 Tons |

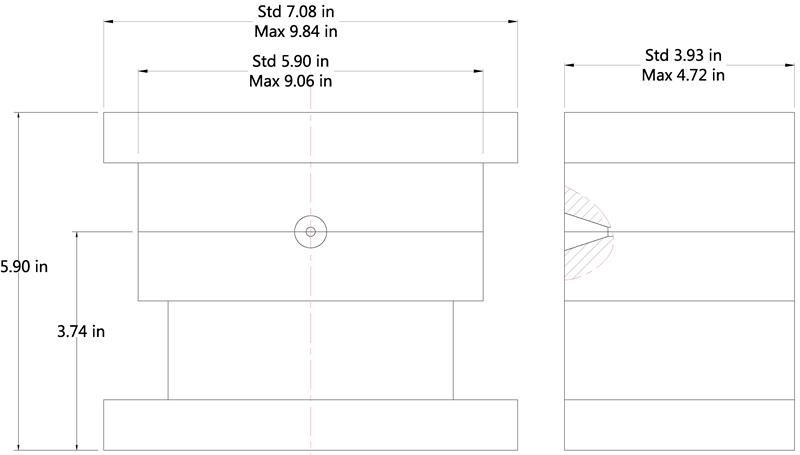

Clamping Stroke | Std.4.92 in (Option 5.91 in) |

Ejector | Air Cylinder |

Ejector Force | 980 N |

Ejector Stroke | 0.39 in |

Control System | 7”HMI , PLC controlled |

Safety Protection | dual palm buttons , light curtain , emergency stop buttons |

Mold Set Size | 7.09 in x 3.94 in x 5.91 in / 35.27 lbs |

Max. Mold Set Size | 9.84 in x 4.72 in x 5.91 in |

Dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.